Pioneering Additive Manufacturing Since 2014

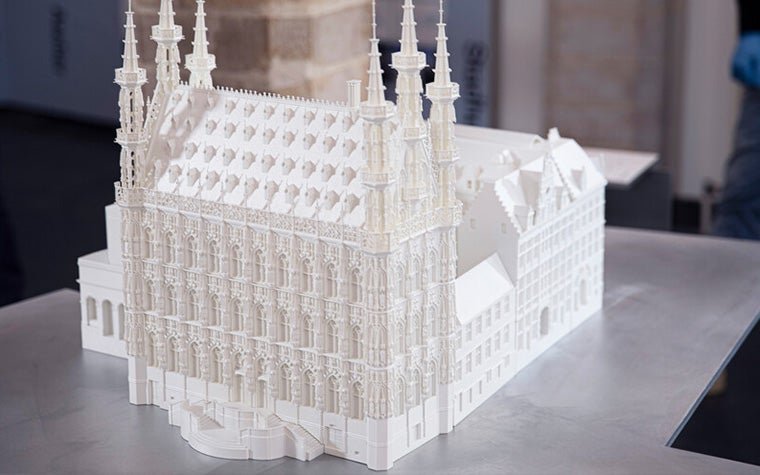

Precision3D was founded by a team of mechanical engineers who recognised that businesses across the United Kingdom needed faster, more affordable access to professional-grade 3D printing. What started as a small workshop in the Midlands with two FDM printers has grown into a fully equipped additive manufacturing bureau serving clients in aerospace, automotive, medical, architecture, and consumer product sectors.

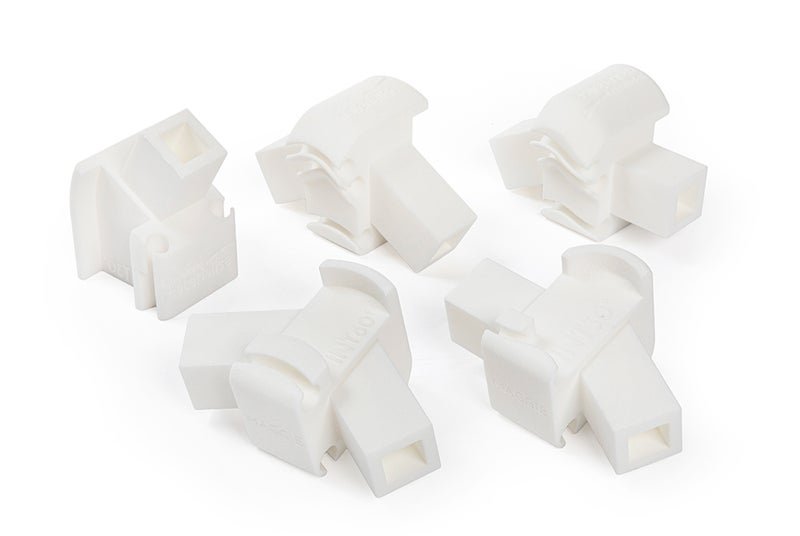

Over the past decade I have invested heavily in the latest printing technologies, post-processing equipment, and quality management systems. My ISO 9001 certified facility houses industrial-grade machines from Formlabs, HP, EOS, and Ultimaker, enabling me to handle everything from delicate micro-detail resin prints to large-format functional prototypes with equal precision.

I believe that exceptional 3D printing is about far more than owning the right machines. It demands experienced operators who understand material science, design-for-manufacture principles, and the real-world performance requirements of every part they produce. That commitment to expertise is what sets Precision3D apart from the competition.

View My Services